Ọnụ ụzọ PVC na ahịrị Extrusion Profaịlụ

Nyocha oru ngo

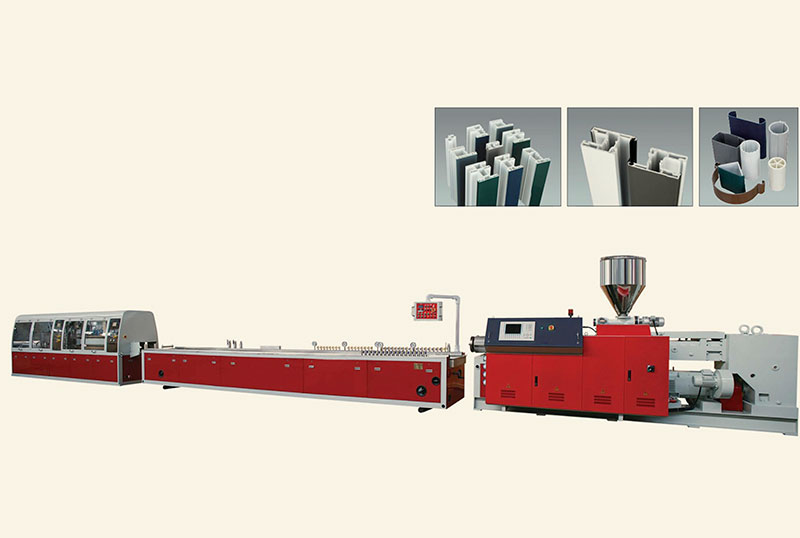

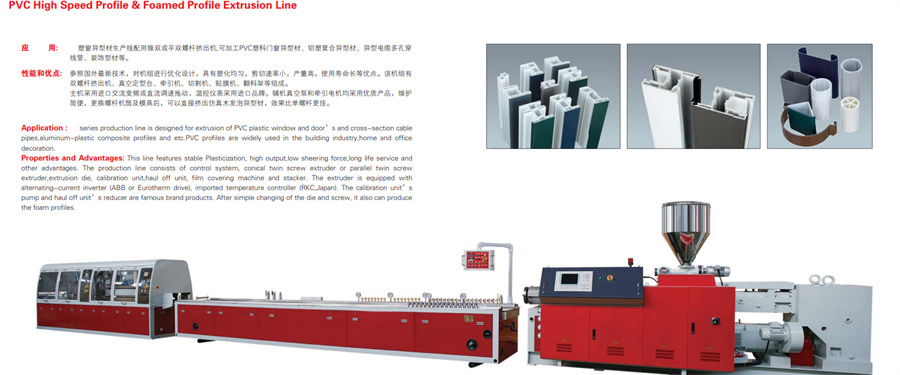

Dị ka ihe gị chọrọ, anyị ga-achọ ịkwado SJZ65/132 PVC Profile Extrusion Line.Ahịrị extrusion a bụ nke SJZ65/132 Conical Twin-screw Extruder na igwe enyemaka mgbada.Biko lelee ozi n'okpuru:

1.1 Njirimara ihe

Ihe ndabere 1.1.1:

- PVC ntụ ntụ:

- CaCo3:

1.1.2 Mgbakwunye:

- Njikọta

- Mmanu mmanu

- 1.1.3 Ụdị ihe

- Ihe niile kwesịrị ịgwakọta kpamkpam.

Ngwaahịa emechara: Profaịlụ PVC;

Ike mmepụta: 150 ~ 250kg / h (dabere na ngwaahịa emechara

Ahịrị mmepụta niile gụnyere:

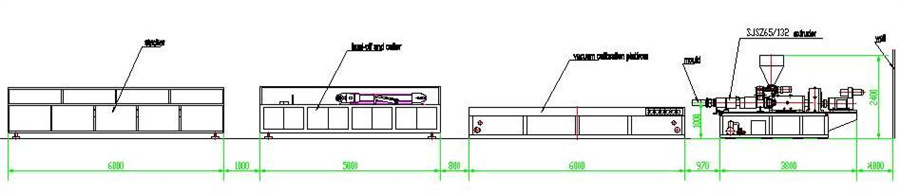

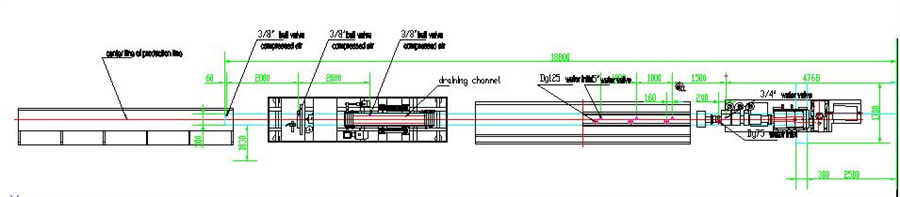

plastic ntụ ntụ ịghasa loader → SJSZ65/132 conical ejima ịghasa extruder → Ebu → Calibrator table → Kpopu igwe → igwe na-egbutu → 6meters stacker

Nkọwa nka na ụzụ

SJZ65/132 PVC profaịlụ extrusion ahịrị

| Mba. | Aha | Foto igwe | Qty. | Nkọwa nka na ụzụ | |

| 1 | ZJ300 ihe ntanetị |  | 1 | Enyere ikike nnyefe: 300kg / h | |

| Ike moto: 1.5kw Dayameta mmiri: Φ36mm Ihe: igwe anaghị agba nchara | |||||

| 2 | SJZ65/132 conical ejima-ịghasa extruder |  | 1 | 2.1 kposara 2.2 gbọmgbọm 2.3 moto na-anya ụgbọ ala 2.4 usoro nri 2.5 sistemu oghere 2.6 nkwụnye 2.7 Igwe eletriki isi Usoro nchekwa onwe ya | |

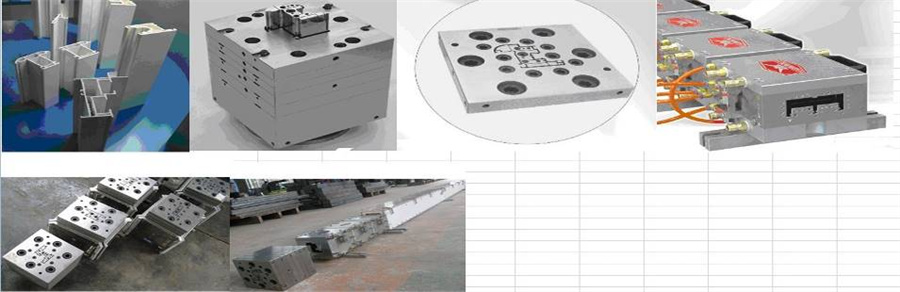

| 2.1:dayameta conical 65/132 mm maka drainpipe PVC na ọkpọkọ mmiri. Ihe nke skru: 38CrMoAl Ngwọta dị n'elu: nhazi nitriding, ọkpụrụkpụ: 0.6 ~ 0,8mm, Polishing Ọsọ na-atụgharị (ntụgharị counter): 1-34.7 rpm / min 2.2 Barrel: dayameta conical 65/132 Nhazi ime: nitrided na ọkpụrụkpụ: 0.6 ~ 0.8mm Mpaghara ikpo oku: 4 Ọnọdụ kpo oku: Cast alumina + igwe anaghị agba nchara Ike ikpo oku: 22kw Ụdị oyi: Ndị na-akwado ikuku: 3 Set 2.3 moto ịnya ụgbọ ala: Ike moto: 37kw Ụdị moto = AC 2.4 Sistemụ nri: Ike ndọda na ịghasa usoro inye nri dosing Na igwe anaghị agba nchara hopper Sistemụ inye nri dose: moto: 1.5kw Nri aka uwe na okirikiri mmiri jụrụ 2.5 Sistemụ na-ekpochapụ ikuku: Mgbapu mgbapụta: 1 set Ọkwa agụụ = 0 ~ 0.075 Mpa 2.6 nkwụnye: (Ngalaba ntinye): Ihe: #40steel Chrome plated, ụdị convergent nke ime Usoro njikọ na anwụ: clamping block + bolt Ihe mmetụta mgbaze nrụgide na thermocouple 2.7 Onye na-ebunye akụkụ eletriki isi: Inverter: ABB ma ọ bụ DELATA Onye kọntaktị: Schneider ma ọ bụ SIEMENS Mgbanwe ikuku: Schneider Relay: Omron Onye na-ahụ maka okpomọkụ: RKC 2.8 Sistemụ nchekwa onwe: N'elu nchebe nke moto ugbu a N'elu nrụgide nchebe nke ịghasa. | |||||

| 3 | YF240 calibration ikpo okwu |  | 1 | 3.1 Akụkụ mpụta 3.2 Vacuum mgbapụta 3.3 Mgbapu mmiri 3.4 Ndozi ụzọ atọ: A na-eme akụkụ mmiri kọntaktị site na igwe anaghị agba nchara. | |

| 3.1 Akụkụ mpụta: Lx W x H: 6000x1100x1000mm (nwere ike idozi) 3.2 Mgbapu oghere: Mgbapu mgbapụta: 3x5.5KW; Mmalite: Yuanli, China 3.3 Mgbapu mmiri: Mgbapu mmiri: 1 × 4KW; Mmalite: Guangzhou, China 3.4 Ndozi ụzọ atọ: Iga n'ihu na azụ nwere moto 0.75kw Oke: ± 1000mm Elu na ala, aka ekpe na aka nri ejiri aka hazie ya Oke: elu na ala: ± 150mm Ntugharị aka ekpe na aka nri: ± 50mm | |||||

| 4 | DYⅢQ Mbupu na cutter (jikọtara) |  | 1 | 4.1 Nwepu 4.2 Cutter | |

| 4.1 Nwepu Ọsọ nfe: 0-3m/min; Ike moto: 5.5KW; Obosara katapila: 210mm; Ogologo katapila: 2200mm; Mkpọchi pneumatic; Nabata holip ma ọ bụ ABB inverter; 4.2 Cutter Ike moto: 2.2KW; Ike moto na-anakọta ihe mkpofu: 1.5KW; Dayameta nke nkwọ: 500mm; Oke ịkpụ: 200mm; Na ngwaọrụ nchịkọta scrap; | |||||

| 5 | Tebụl ntụ ntụ |  | 1 | 5.1 Tebụl ndụmọdụ: Ogologo Usoro njikwa Oke mmezi ịdị elu | |

| Ogologo:6,000mm Usoro njikwa:Pneumatic Site na skru iji dozie oke ịdị elu:0 ~ 180 mm | |||||

6.Mixing equipments

1. Ngwa:

Gwakọta akụrụngwa

2. Mpụta: ≤500

3. Akụkụ akụrụngwa:

① igwekota ọkụ

② igwekota oyi

③ autoloader

4. Parameter

| Nlereanya | / | Otu igwekota SRL-Z300/600 | ||

| ||||

| 1 | Ngwakọta na-ekpo ọkụ | |||

| 2 | mkpokọta olu igwekota ọkụ | L | 300 | |

| 3 | irè olu nke na-ekpo ọkụ igwekota | L | 225 | |

| 4 | ihe dị arọ / ogbe | ㎏/Ogbe | ≤100 | |

| 5 | Mpụta | ㎏/h | ≤500 | |

| 6 | moto ike | KW | 40/55, moto ọsọ abụọ | |

| 7 | ike kpo oku | KW | 12 | |

| 8 | igwekota na-ekpo ọkụ na-atụgharị ọsọ | r/min | 475/950 | |

| 9 | Ọnụọgụ agụba na-akpali akpali | pcs | 3 (1Cr18Ni9Ti) | |

| 10 | oge agwakọta | min/ogbe | 8-10 | |

| igwekota oyi | ||||

| 1 | olu igwekota oyi | L | 600 | |

| 2 | irè olu nke jụrụ igwekota | L | 450 | |

| 3 | moto ike | KW | 11 | |

| 4 | ihe nke jụrụ mixer agụba | / | ZG1Cr18Ni9Ti | |

| 5 | na-akpali agụba na-atụgharị ọsọ | r/m | 130 | |

| 6 | usoro njikwa ebuli | / | pneumatic | |

| 7 | Usoro jụrụ oyi | / | mmiri jụrụ oyi | |

| 8 | oge jụrụ oyi | min/ogbe | 10-12 | |

| Eletriki | ||||

| 1 | AC kọntaktị | / | Schneider | |

| 2 | Onye na-ahụ maka okpomọkụ | / | Omron | |

| Onye na-ebu akpaaka | ||||

| 1 | Dayameta tube tube | mm | 101 | |

| 2 | Ịchaji ike moto | KW | 1.5 | |

| 3 | Tinye ike moto ihe onwunwe | KW | 0.55 | |

| 4 | Olu nchekwa | kg | 80 | |

| 5 | Ihe nke hopper nchekwa na tube | / | Igwe anaghị agba nchara | |

7 Plastic crusher (nhọrọ)

Ngwa: gwepịa akụkụ PVC mkpofu maka iji ihe eji emegharị ihe

| ihe nlereanya | SWP - 400 |

| |

| Dayameta nke agụba na-atụgharị | 400mm |

| Ọnụ ọgụgụ agụba na-atụgharị | 5 |

| Ọsọ na-atụgharị | 500r/min |

| Ọnụ ọgụgụ agụba edobere | 2 |

| Oghere ihuenyo (mm) | 10 |

| Ikike ịkụpịa | 350-450 n'arọ / h |

| Ike (kw) | 13.2 |

| Ọnụ na-enye nri (mm) | 375*320 |

| Ibu(kg) | 980 |

| Nha (mm) | 2500*1200*2000 |

8. PVC pulverizer (nhọrọ)

Ngwa: Iberibe PVC egwepịara egwepịa n'ime ntụ ntụ

| |

| Dayameta nke ọnụ ụlọ ngwepịa (mm) | 400 |

| Ọnụọgụ nke rotor | 3 |

| Isi ngwa ngwa (r/min) | 3400-3700 |

| Ike moto (kw) | 30 |

| Ike mmepụta (kg/h) | 50-150 |

| Ibu (kg) | 1000 |

Ahịrị na-asọpụta na nhazi maka ahịrị mmepụta profaịlụ PVC

Ngwa

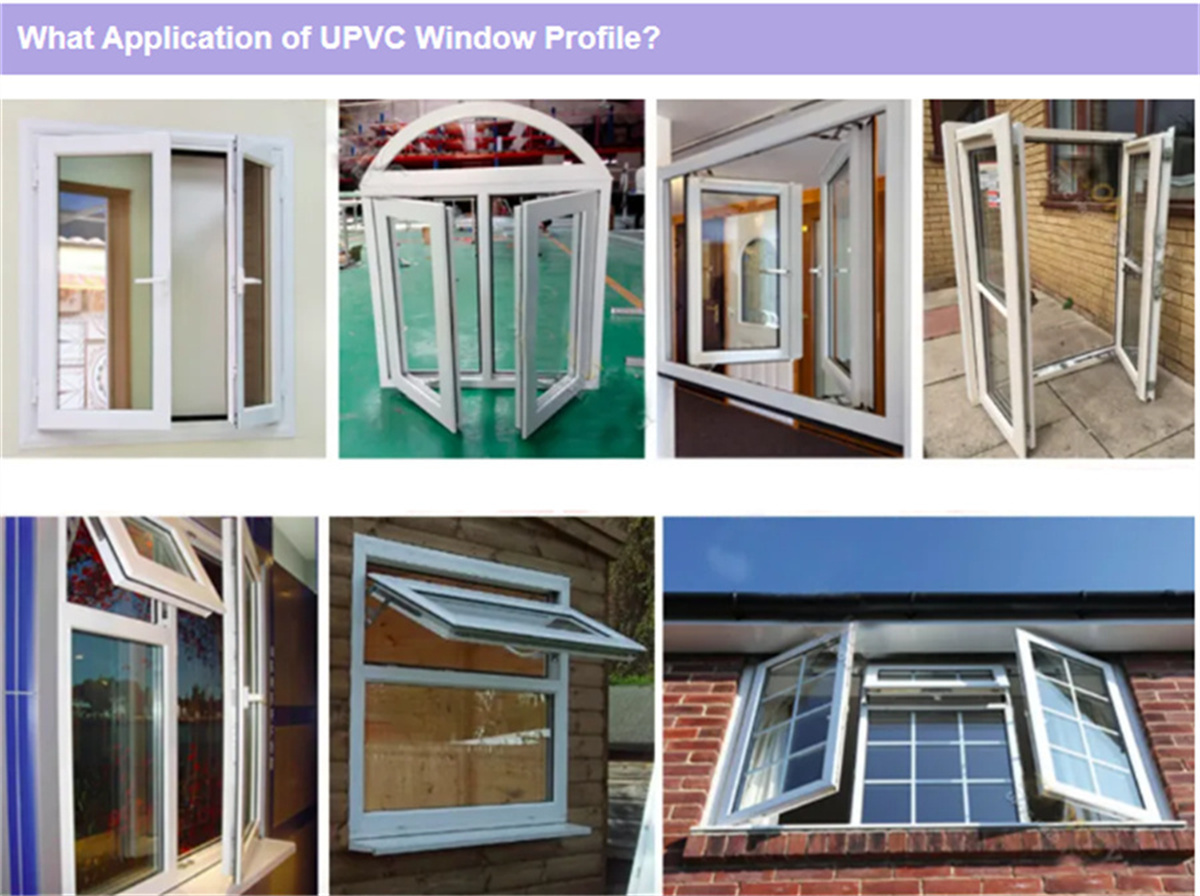

Kewara dị ka usoro mmeghe:

Window edoziri, windo nkwusioru nke elu, windo nkwusioru etiti, windo nkwudo dị ala, windo kwụ ọtọ, windo mepere emepe, windo pulley flat, windo pulley, ọnụ ụzọ na windo mepere emepe, ọnụ ụzọ na windo, windo na-ebugharị ewepụghị, ọnụ ụzọ mpịachi, mmiri ala. ọnụ ụzọ, na-ebuli ọnụ ụzọ na-amị amị, na-akwanye ọnụ ụzọ mpịachi, ọnụ ụzọ mkpọda azụ n'ime.

Profaịlụ PVC nwere njirimara dị ka nkewa ụda, nnabata ụda, nkewa okpomọkụ, idebe okpomọkụ, wdg.Ihe anaghị ere ọkụ, ọ dị mma maka ojiji.

Usoro niile nke ngwaahịa nwere ihe akaebe nke mmiri, ihe akaebe mildew, nguzogide mmiri, mmetụta na-eguzogide vibration ya ma ọ bụrụ na ọ dị mma.Usoro niile nke ngwaahịa nwere ihe na-egosi ihu igwe, ọnya ya nwere ike ịdịgide ruo mgbe ebighị ebi, ọ dịghị mfe ịka nká.Ngwaahịa a dị ọkụ, nchekwa & njem, ihe owuwu na-adaba adaba.Ngwaahịa a nwere ike iji ngwá ọrụ nkịtị rụọ ọrụ maka ihe osisi.Enwere ike ịme ihe ọkụkụ, ịwa ahụ, ntu, planing, bonding dị ka ihe osisi.Ọ dabara adaba maka ịkpụzi ọkụ, ịgbado ọkụ na nhazi mpịaji.Enwere ike ịgbanye ya, ọ nwekwara ike jikọta ya na ihe PVC ndị ọzọ.Elu ngwaahịa a dị nro, enwere ike ibipụta ya.(Hichaa elu tupu ebipụta ya.)